Pcb Assembly Manufacturing Process

Pcb Assembly Process Andwin Circuits Pcb manufacturing process a very difficult and complex. here we will learn and understand the process with the help of flowchart and video. majority of printed circuit boards are manufactured by applying a layer of copper over the entire surface of the pcb substrate material either on one side or both sides. Pcb assembly, or pcba, is the intricate process of assembling and soldering all components and connectors onto a circuit board. as component sizes shrink, pin density increases, and product iterations accelerate, conventional manual techniques struggle to meet the demands of this evolving landscape.

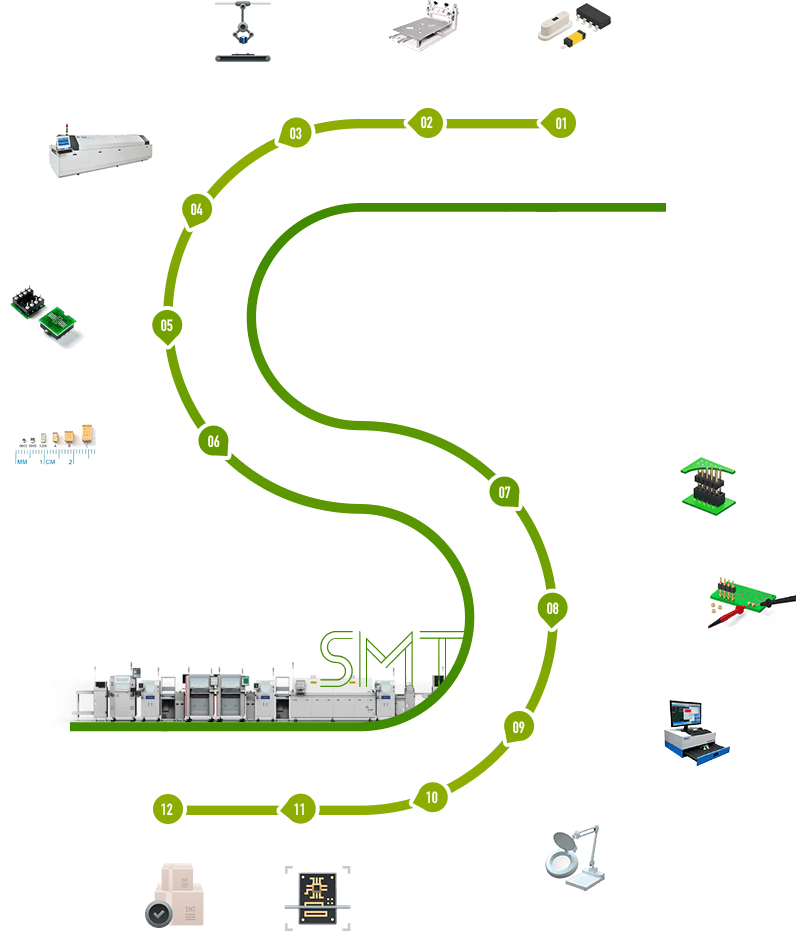

Pcb Assembly Process Apollopcb Pcb assembly is the process of populating a circuit board with all the desired components. it involves dfa, smt, and through hole components placement, testing, and final inspection. The pcb assembly process comprises two main techniques: smt (surface mount technology) and tht (through hole technology). these methods involve distinct processing steps and are selected based on factors such as the pcb's specifications, manufacturing speed, and level of automation. The pcb fabrication process can be grouped into three main steps: imaging, etching, and lamination. advanced pcb shops use sophisticated equipment to produce boards with extremely fine features and tight tolerances. Whether you are designing a simple single sided pcb or a complex multi layer hdi pcb, this knowledge will help you navigate the manufacturing process and produce high quality pcbs that meet your specific requirements.

Pcb Assembly Manufacturing Process Jlcpcb Factory Tour The pcb fabrication process can be grouped into three main steps: imaging, etching, and lamination. advanced pcb shops use sophisticated equipment to produce boards with extremely fine features and tight tolerances. Whether you are designing a simple single sided pcb or a complex multi layer hdi pcb, this knowledge will help you navigate the manufacturing process and produce high quality pcbs that meet your specific requirements. The final step in the pcb manufacturing process is assembly, where electronic components are placed and soldered onto the board to create a fully functional circuit. this stage transforms the bare pcb into a ready to use electronic device, whether it’s a simple led light or a complex smartphone motherboard. What steps are involved in the pcb manufacturing process? the pcb design phase comprises two parts: schematic capture and pcb layout planning. schematic capture involves blueprinting and diagramming the circuitry, while pcb layout planning involves designing the physical board. 2d and or 3d models of the pcb are often created in this process. Assembly of printed circuit boards (pcbs) is an integral and vital aspect of electronics production, and this comprehensive guide seeks to walk you through each step of pcb assembly and its myriad techniques and processes involved. 1. pcb assembly process: understanding pcb assembly. Pcba (printed circuit board assembly) manufacturing is the process of assembling electronic components onto a printed circuit board (pcb) to create a functional electronic device. the process involves several steps, including pcb design, component sourcing, assembly, testing, and packaging.

7 Manufacturing Process Of Pcb Assembly The final step in the pcb manufacturing process is assembly, where electronic components are placed and soldered onto the board to create a fully functional circuit. this stage transforms the bare pcb into a ready to use electronic device, whether it’s a simple led light or a complex smartphone motherboard. What steps are involved in the pcb manufacturing process? the pcb design phase comprises two parts: schematic capture and pcb layout planning. schematic capture involves blueprinting and diagramming the circuitry, while pcb layout planning involves designing the physical board. 2d and or 3d models of the pcb are often created in this process. Assembly of printed circuit boards (pcbs) is an integral and vital aspect of electronics production, and this comprehensive guide seeks to walk you through each step of pcb assembly and its myriad techniques and processes involved. 1. pcb assembly process: understanding pcb assembly. Pcba (printed circuit board assembly) manufacturing is the process of assembling electronic components onto a printed circuit board (pcb) to create a functional electronic device. the process involves several steps, including pcb design, component sourcing, assembly, testing, and packaging.

Pcba Capabilities Pcb Assembly Process Fastpcb Assembly of printed circuit boards (pcbs) is an integral and vital aspect of electronics production, and this comprehensive guide seeks to walk you through each step of pcb assembly and its myriad techniques and processes involved. 1. pcb assembly process: understanding pcb assembly. Pcba (printed circuit board assembly) manufacturing is the process of assembling electronic components onto a printed circuit board (pcb) to create a functional electronic device. the process involves several steps, including pcb design, component sourcing, assembly, testing, and packaging.

Comments are closed.