Pcb Manufacturing And Assembly Process

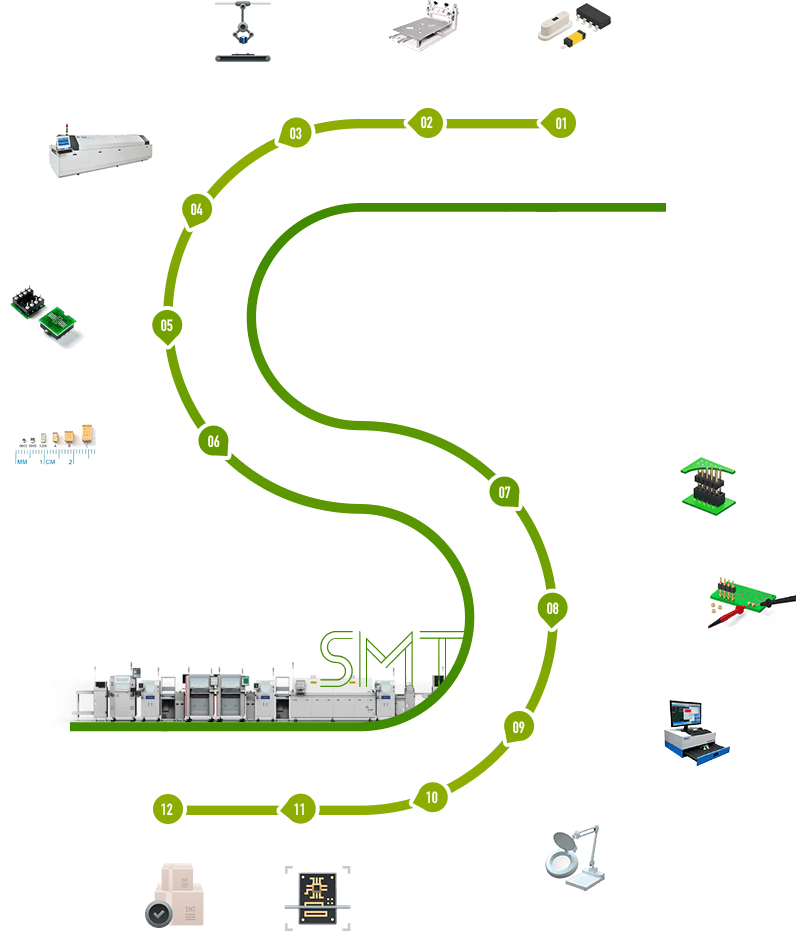

Pcb Assembly Manufacturing Process Both amateur electronics enthusiasts and professional engineers who grasp pcb manufacturing find themselves uncovering fundamental technological insights. we will guide you through each phase of pcb fabrication and assembly with easy to understand explanations suitable for newcomers to electronics. Explore the step by step pcb manufacturing assembly process, from design to testing. learn how precision and quality control ensure reliable electronic products for various applications.

Pcb Assembly Manufacturing Process Discover the pcb manufacturing process from design to assembly. learn how precision engineering transforms concepts into functional circuit boards. A pcb is a flat board made of non conductive material, usually fiberglass, with a layer of conductive pathways and components mounted on it. it is used to connect and support electronic components in various devices, enabling them to function as intended. This comprehensive guide will walk you through the pcb manufacturing process step by step, covering everything from design and material selection to final testing and inspection. by the end of this article, you will have a thorough understanding of how pcbs are made and the key considerations at each stage of the process. Printed circuit board (pcb) assembly is a critical part of turning an electronic design into a functional product. whether you’re working on a prototype or preparing for mass production, understanding the step by step pcb assembly process can help you avoid delays, reduce costs, and ensure product quality.

Pcb Assembly Process Apollopcb This comprehensive guide will walk you through the pcb manufacturing process step by step, covering everything from design and material selection to final testing and inspection. by the end of this article, you will have a thorough understanding of how pcbs are made and the key considerations at each stage of the process. Printed circuit board (pcb) assembly is a critical part of turning an electronic design into a functional product. whether you’re working on a prototype or preparing for mass production, understanding the step by step pcb assembly process can help you avoid delays, reduce costs, and ensure product quality. In this comprehensive guide, we’ll dive deep into the process of pcb production and assembly, giving you a behind the scenes look at how these components are actually created and assembled. so, read on. before a single circuit is printed or a component is placed, the design stage sets the groundwork for pcb production and assembly. Pcb manufacturing is the foundational process of creating the bare printed circuit board, transforming design specifications into a physical substrate ready for component assembly. Understanding the assembly and manufacturing process goes a long way to allow informed decisions concerning quality and efficiency. pcb assembly can be said to include the placing and soldering of electronic components onto the bare circuit board. Printed circuit board (pcb) manufacturing is the manufacturing, assembly, and production of electronic component printed circuit boards. boards are the foundation for the electrical interfaces of the components, signal, and power, which are desirable. it starts as a schematic design, followed by a physical board design.

Comments are closed.